Plastic waste can now power jets and cars as scientists crack global problem in new study

Plastic waste—which has long been considered a bane for the environment—can be turned into jet fuel and diesel, according to a new study.

Researchers were able to produce a mixture of 85% jet fuel and 15% diesel fuel from a mixed variety of waste plastic products like water bottles, milk bottles, and plastic bags. The team says that the method is simple, easily scalable and could be deployed in large facilities.

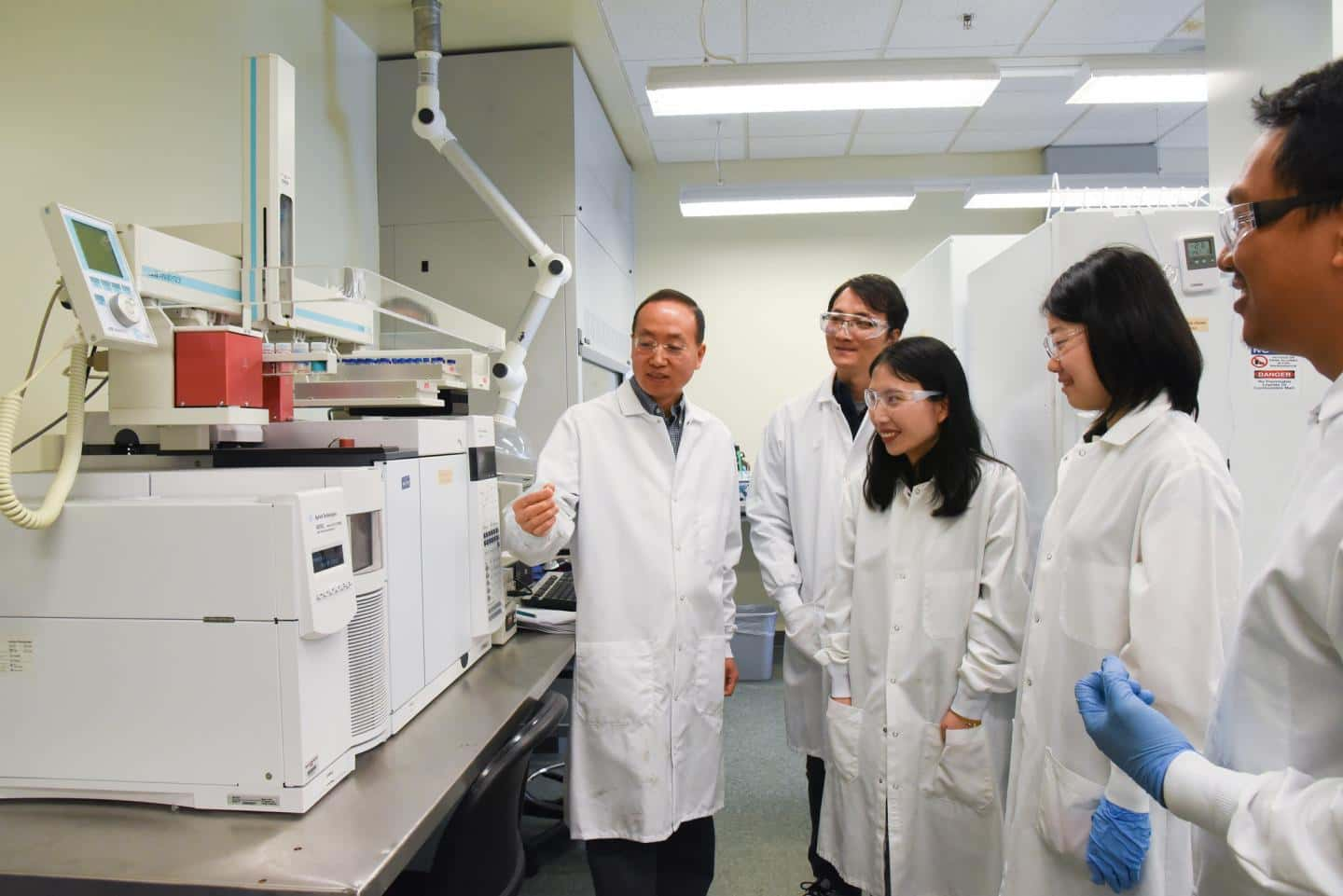

Dr. Hanwu Lei, an associate professor at Washington State University who was part of the study, told MEA Worldwide (MEAWW) that they plan to take forward their findings by including "all types of waste plastics and also a mixture of varied plastics to develop a versatile conversion process which can be used everywhere in the world."

300 million tonnes of plastic waste is generated every year, according to the United Nations Environment Programme, and most of it ends up in landfills posing a great danger to the natural environment and human health.

To tackle the growing issue of waste plastic, researchers, led by Washington State University, have now found a way to turn plastic waste into jet fuel.

"Fossil fuels derived plastic products play a pivotal role in enhancing modern lives, and approximately 405 million tonnes of primary plastics entered the use phase in 2015, which is predicted to continuously increase by 4% in the forthcoming years, meanwhile leading in parallel to the growing of generated waste plastics," researchers said in a paper published in the journal 'Applied Energy'.

The researchers pointed out that most of the plastic waste is discarded as a large percentage of it cannot be recovered. "The waste plastics end up in the landfill and incineration induce a danger towards the natural environment, human health, and even lives from plankton to whales in oceans and waterways, which brings severe impacts on the ecosystem and economy," the study claims.

"Therefore, developing a facile, efficient, and cost-effective method is in high demand to tackle plastic pollution and simultaneously convert these waste plastics into value-added energy products."

The study was supported by The Agriculture and Food Research Initiative of the National Institute of Food and Agriculture, United States Department of Agriculture.

To produce jet fuel, the researchers melted plastic waste at high temperature with activated carbon.

"Waste-plastics-to-fuel production was developed through one-pot catalytic pyrolysis of waste plastics over renewable biomass-derived carbon catalysts. The work provides a fresh and new way of renewable biomass utilization as a robust carbon catalyst, especially for solving the worldwide problem of waste plastics. Activated carbon is relatively easy to get from biomass, such as corn stover or wood. The conversion process is relatively simple to operate, and it should be a good option for many developed and developing countries. It will also be good for island nations where fuel prices are high, and landfill options are limited," Dr. Hanwu Lei, Associate Professor, Department of Biological Systems Engineering, Washington State University, told MEA Worldwide (MEAWW).

According to an official release on EurekAlert, the research team tested low-density polyethylene and mixed a variety of waste plastic products, like water bottles, milk bottles, and plastic bags, and ground them down to around three millimeters, or about the size of a grain of rice. According to the researchers, it is difficult to break down plastic, and a catalyst has to be added to help break the chemical bonds. There is a lot of hydrogen in plastics, which is a primary component in fuel.

"The plastic granules were then placed on top of activated carbon in a tube reactor at a high temperature, ranging from 430 degree Celsius to 571 degrees Celsius (806 to 1,060 Fahrenheit). The carbon is a catalyst or a substance that speeds up a chemical reaction without being consumed by the reaction. Once the carbon catalyst has done its work, it can be separated and re-used on the next batch of waste plastic conversion. The catalyst can also be regenerated after losing its activity," said the release.

After testing several different catalysts at different temperatures, the best result they had was able to produce a mixture of 85% jet fuel and 15% diesel fuel. The team says that the method is simple, easily scalable and could be deployed in large facilities.

"The present work could provide an efficient, facile, and cost-effective route of transportation jet fuel production from waste plastics," the researchers conclude in the paper.

Dr. Lei told MEAWW that they plan to take forward their findings by including "all types of waste plastics and also a mixture of varied plastics to develop a versatile conversion process which can be used everywhere in the world."

According to Dr. Lei, the method will not only reduce waste, very little of what is produced will be wasted. "We can recover almost 100% of the energy from the plastic we tested. The fuel is of very good quality, and the byproduct gasses produced are of high quality and useful as well," he said in the release.